About Zephyr Metal Trading L.L.C

Zephyr Metal Trading L.L.C established itself as an independent & dedicated trading company. Zephyr is one of Asia's leading suppliers of ferrous and non-ferrous products and has grown steadily and today has a strong client network throughout the world.

We are an international trading company based in Dubai interested in downstream steel porcessing and distribution, with activities ranging from the collection and processing of scrap metal through of the marketing and distribution to a wide range of steel products to manufactures.

We are specialized in customized Pipes, Flanges, Valves, Sheets, Plates, H/I Beams etc... in all standards like ASTM, ASME, ANSI, API, DIN, EN, ISO, BS, JIS etc... and differenct materials like Stainless Steel 316, 316L, 304, Carbon Steel, Duplex etc... with in stipulated time. We have good network and able to source from many destinations like U.S.A, U.K, Europe, India, China, Taiwan, Korea etc... with third party inspection by BV, TUV, DNV, ABS, SGS, IBR, Moody International etc... and mill certificate as per EN 10204 : YYYY / 3.1 & 3.2. We also can supply small quantities, competitive price is our key strength.

We have a network of bulk suppliers of steel scrap from various Origins on very competitive price, inquire with confidence, & become a part of reliable supply chain network, we are very much proud of our customer services & assistances during & after the deal, if you have tried the rest now it is time to contact the best.

We are regular direct end buyers and importers of all types of Primary, Secondary and scrap metals for trading to all major Southeast Asian countries. Zephyr provides a competitive advantage with its customer-driven advanced technology solutions that optimizes your needs. India is Zephyr's largest national market followed by all major Southeast Asian countries, part of Australia and South Africa and few other American and European nations. Our buyers include steel mills, foundries, metal fabricators, metal brokers, trading houses, construction companies, engineering companies and off shore companies.

Zephyr's success has been achieved through the adoption of a collaborative, open and ethical internal culture. The company has an experienced and skilled management team and workforce whose commitment is reflected in its swift growth. Growth and strong market positions have been achieved through sincere efforts, teamwork, time management, dedication and investments.

The company also places great importance on research, quality control and product development, including sourcing technology from overseas and employing it effectively. Zephyr is committed to produce quality products and services, providing value for customers & employees with rewarding careers. Today, the company stands as a major force in the steel industry and a key contributor to the Asian economy.

Our Vision

- Making the earth a better place to live-in by providing dedicated recycling services for a cleaner and greener environment.

- Amplify our business; set foot into various other markets than steel; become a pioneer in business world.

As a company, and as individuals, we value:

- Word as our bond.

- Unity, integrity and honesty

- Open mindedness and respectfulness.

- Taking on big challenges and facing them.

- Understanding, responsibility and excellence.

- Long-term relationship and not short-term gains.

- Passion for customers, partners and technology.

- Constructive self-criticism, self-improvement, and personal excellence.

- Accountability to customers, shareholders, partners, and employees for commitments, results, and quality.

Our Pursuit

Recycling

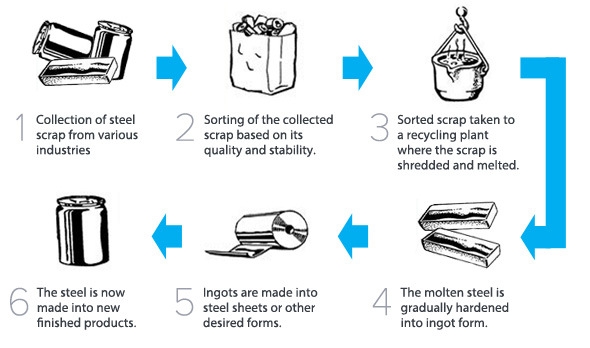

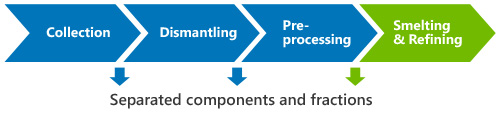

Perplexed!!! As our profile says we are a metal trading company, playing a major role in the society as recyclers. Now let's see how the process goes on:

THE PROCESS:

Steel recycling saves a lot of energy. It is much more energy efficient to use steel scrap to make new steel than to mine the iron ore and then smelt it in a blast furnace. It takes about 75 percent less energy to make steel from recycled materials than it does from iron ore. That's why today's steel manufacturers always use some steel scrap to make new steel products.

After steel scrap is collected from homes, recycling centers or waste-to-energy plants, it is shipped to one of the companies that buy old steel-steel mills, iron and steel foundries, scrap dealers and detinners. Steel scrap are melted in a furnace and then poured into casters that continuously roll and flatten the steel into sheets. Recycled steel can be made into new cars, girders for buildings, or new food cans. All new steel products contain at least 25 percent recycled steel with some containing nearly 100 percent recycled steel. Steel can be recycled again and again. It does not lose any of its strength or quality in the recycling process. It can be a never-ending process that continues to save energy and resources.